电动执行器钢性防火罩JSAVE柔性防火罩是工厂管理中一种有效保护设备的措施,它能将炼油厂、石油平台、石油化工、热电站、电器、造船厂和军工等场所因火灾而产生的危害与损失降至Z低的详细信息夹克:柔性护套钢外壳:钢箱

The products was tested in fire laboratories as the

time-temperature curve of UL1709 产品测试实验室为ul1709火的温度时间曲线

防护材料的快速上升试验。

ul1709的时间温度曲线是严重的烃类火灾曲线这是可能发生在炼油厂,

石化和离岸平台。阀门执行机构应为ul1709火灾升温曲线下30分钟运行周期的证明。 海洋平台爆炸试验与研究,喷射火试验为iso22899 1 is required。 我们的制造业是膨胀型涂料测试为2.0和J

- 90酒吧爆炸喷射火 纤维素火点火后有缓慢的火焰温度上升.。标准的纤维素火灾温度与时间曲线应是参考文献:BS476,IMO决议A517(13),ISO r834和国际海上人命安全公约。典型的辐射值5分钟后点火为50千瓦/平方米。 纤维素火灾温度与时间曲线的美国(ASTM E119,nfpa251,ul263)稍快。

烃类火灾碳氢化合物火灾燃烧后火焰温度迅速上升。标准烃火 温度与时间曲线应是BS476 20和ul1709。典型的稳态温度为1100 oC。

典型的辐射值5分钟后点火为160千瓦/平方米。喷射火

喷火是湍流扩散火焰,一个稳定的释放加压液体燃烧产生的

或气态燃料。他们是亲民的材料可能需要承受最严重的火灾场景,

考虑到侵蚀的影响,也显着较高的燃烧率,由于湍流燃料-空气混合。

测试程序将ISO

22899-1。爆破试验 典型的最大阻力为对象的表面面积小,如结构构件

假定是0.2到1巴。

对认可的独立机构进行动态爆炸试验的系统,应给予优先考虑。

1.1 These requirements describe a test

method measuring the resistance of protective materials to rapid-temperature-rise

fires. 1.1 本文规定了一个量测防护材料在快速升温火环境下耐火性能的实验方法. 1.2 The test method covers a full-scale

fire exposure, intended to evaluate the thermal resistance of protective material

applied to structural members and the ability of the protective material to

withstand the fire exposure. 1.2 实验方法包含一个全尺寸火灾实验,用来评价应用于结构构件的防护材料的耐热性能和耐火性能. 1.3 The test method also covers a

small-scale fire exposure, intended to evaluate the ability of protective

materials to withstand a variety of environmental conditions anticipated. 1.3实验方法同时也包含了一个小比例火灾实验,用来评价防护材料在多种预期环境下的耐受能力. 2 General 2.总则 2.1 Units of measurement 2.1计量单位 2.1.1 Values stated without parentheses

are the requirement. Values in parentheses are explanatory or approximate

information. 2.1.1 未加括弧的数值为精确值,加注括弧的为解释值或近似值. 2.2 Undated references 2.2没有标注日期的内容 2.2.1 Any undated reference to a code or

standard appearing in the requirements of this standard shall be interpreted as

referring to the latest edition of that code or standard. 2.2.1 在本标准中出现的任何没有标注日期的准则或规范都可认为是参照最新版本的准则或规范。 FULL-SCALE TEST METHOD 足尺寸实验方法 3 Furnace Control 3加热炉(马福炉?)控制 56°C) within 5 min from the start of the

test. The fire environment is to be controlled by reproducing the furnace

temperatures recorded during the furnace calibration method specified in Furnace

Calibration, Section 4. This temperature is to be maintained throughout the

remainder of the fire test as shown in Figure 3.1.±100°F (1093 ±16 kW/m2) and an average

temperature of 2000 ±5000 Btu/h·ft2 (204±3.1 The fire environment

within the furnace is to develop a total heat flux of 65,000 |

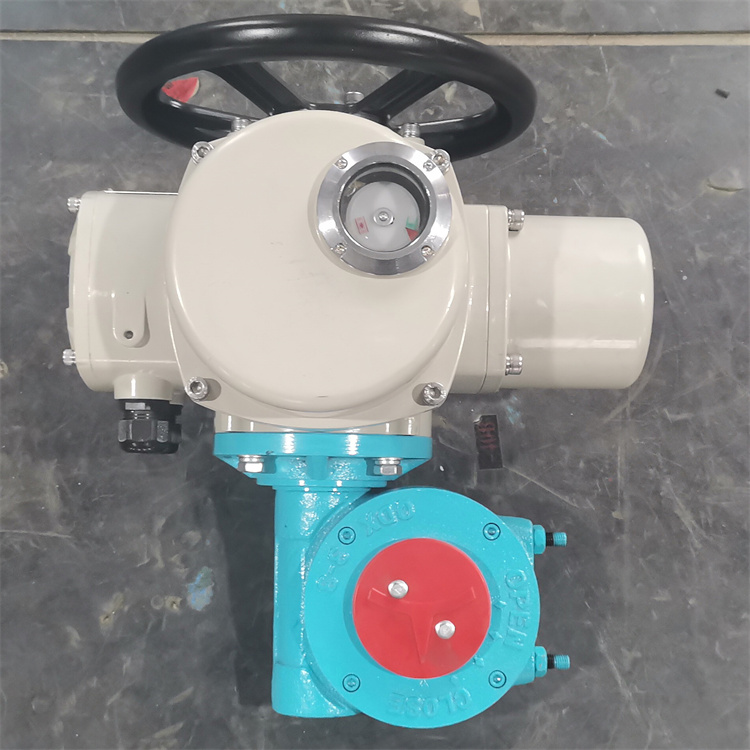

- 阀门执行器

- 电动铁球阀

- DZW10-18W/3 开关型 AC380V 多回转电动执行器

- NSDM11AE-35-NO-WA

- 柔性防火罩

- DZW15-18TZ/3智能一体式开关型电动执行器

- 储罐防火罩制造

- 齿轮齿条液压执行器

- DZW20-18TZ/3智能一体式调节型电动执行器

- 齿轮齿条液压执行器

- DDQ10-D3-W3叠加式 大口径蝶阀 球阀电动执行器

- 气控换向阀

- 齿轮齿条液压执行器

- DDJ10-D3-W3角行程 大口径蝶阀 球阀 风门挡板电动执行器

- 齿轮齿条液压执行器

- DDZ10-50-T3直行程调节阀电动执行器

- 齿轮齿条液压执行器

- 电动执行器

- 381LSB-30直行程电动执行器

- PSL202直行程电动执行器

- 风阀驱动器4NM

- SKZ-210直行程电动执行器

- 刚性阀门防火罩

- DCL-310直行程电动执行器